全部分类

四探针自动电阻测试仪

关键词:

所属分类:

产品参数

The QuadMap features tools necessary for engineers to define meaningful test parameters and operators to quickly load a sample and test.

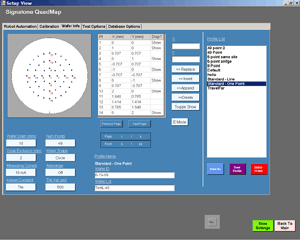

Operators simply place the sample on the vacuum chuck, close the door, enter the ID of the test sample and press the Start button. The sample loads, and begins testing. A typical 50 location test, on a 300mm wafer will complete in less than one minute. During the test, the results table displays each test site’s results and highlights in red for failures.

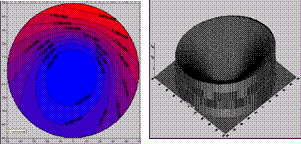

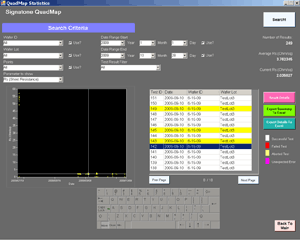

At the conclusion of the test, the data is automatically stored in a database. Operators may view the wafer graphs in up to 5 different formats including 2D black & white, 2D color, 3D, 3D half X and 3D half Y. Statistical results shown include Avg, Std Dev, 1Sigma, Max and Min. Operators may also print a report (printer not included) or export data to a spread sheet and save to a USB flash drive.

Engineers define and create tests to verify the processing tolerances are in compliance. They define the test modes including autorange or current setting, dual configuration, sensitivity and pass/fail tolerances. Additionally, engineers will also define the number of test sites up to 14,000, which probe head is installed, sample size, edge exclusion, etc. Once a test is defined, it is stored in the test list. Of course, Engineers have all of the same privileges as operators and can run the tests desired.

Engineers will also appreciate the powerful trending tool provided by QuadMap. With the data automatically stored into a data base; after a number of tested samples, engineers can sort the results and identify trends effecting the measured samples.

QuadMap is defined for the production environment. Bright polished stainless steel skins and other materials assure Fab ready operation. A modular design assures that if a failure does occur, a field service technician can quickly replace the errant part.

· High speed measurements of thin films, wafers and solar tiles.

· Reports sheet resistance Ohms per square and resistivity in Ohms per cm.

· Available in 150mm, 156mm square, 200mm and 300mm configurations

· Speed: 50 points per minute with standard configuration

· Dual configuration: applies the standard ## to automatically correct for geometric errors caused by probe spacing and/or edge proximity , improving overall accuracy

· Auto-range: finds the ideal current setting to meet the parameters of the standard for measuring.

· Standard range: 1mΩ to 100MΩ per square

· P/N typing

· 5 different 2D and 3D mapping to choose from

· Data is automatically stored and may be exported to a spread sheet.

Optional SECSII/GEM interface allows control and ability to upload data from FAB management system

Key features in all Signatone systems include auto-range and dual configuration. Auto-range automatically finds the ideal current setting to meet the parameters of the standard for measuring. At the first test site, the software controls the current source to step through a number of settings until the measured voltage is in target range as defined by the standard. This current is then used for all subsequent measurements of the sample. Dual configuration mode applies the standard ## to automatically correct for geometric errors caused by probe spacing and/or edge proximity improving overall accuracy.

Signatone offers 3 product families- The QuadMap for production, the QuadPro for R&D and the Pro4 for basic, manual measurements. Each family has a variety of options and configurations. With over 60 configurations to choose from, Signatone has the product that will meet your application.

Lucas Signatone QuadPro Resistivity System

· Reports average resistivity, resistivity standard deviation, average sheet resistance and sheet resistance standard deviation

· Temperature coefficient of resistance (TCR) measurements integrated with automated temperature chuck and source meter (optional).

· Automated 2D & 3D contour mapping

· Employs the dual configuration testing method for improved accuracy and repeatability

· For samples 10 to 300mm

· 1 to 49 NIST traceable automated measurements per sample

QuadPro Automatic System

The QuadPro includes a computer, stepper controller, and base station with either a 200 or 300mm diameter isolated chuck.

The software allows for selecting 1, 5, 9, 25 or 49 points for automated testing and mapping of the test sample. Positioning patterns may be set to either round or square configuration.

The edge exclusion may also be defined. On the first measurement, the software auto ranges the meter finding the best settings for the sample testing. Dual configuration assures that errors introduced by the probe head manufacturer are eliminated, increasing the repeatability and accuracy of measurements. The Software controller automatically steps to each position and records the X-Y position, Sheet Resistance, Resistivity and V/I measurement in a visible table.

Upon completion of the test points, a wafer contour map is displayed. The contour map may be toggled between 2D and 3D viewing. The average and standard deviation of resistivity and sheet resistance display prominately above the contour map.

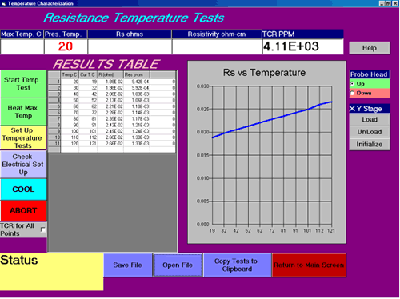

The Temperature Coefficient of Resistance option integrates temperature control of the test sample as well as the automated source meter control and resistance calculations. Integrated with a variety of Signatone thermal chuck systems, the test allows setting of temperature steps in degrees C, dwell time at temperature before reading, starting temperature and ending temperature. Each temperature, and resistance reading is stored in a table and plotted on a graph for analysis.

Signatone offers a variety of thermal chucks and temperature ranges. The standard, most common range is ambient to 350°C. However, different combinations of chucks and controllers could have a low of -55°C to a high of 600°C.

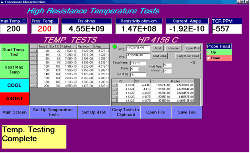

The QuadPro standard configuration includes the Keithley 2400 Source Measurement Meter. This meter allows resistance measurements in the range of 1 milliohm to 2 megaohms. Some of the newer high resistance materials require a greater resistance measurement range. For those applications, Signatone implements the Agilent 4156 Parametric Analyzer along with special triaxial shielding. This configuration increases the range from 100 millohms to 10 gigaohms, see to the right.

Four Point Probe Heads

Signatone offers two probe heads to choose from; the SP4 and the HT4. The SP4 is an inline probe made of delrin and used in most applications. Several choices are available for configuration to your specific application. The three spacings are .040, .050 and .0625 inches. The three pressures available are 45, 85, and 180 grams. Tips are made of Tungsten Carbide or Osmium and a choice of .0016, .005, .010 inches radius.

The HT4 inline four point probe head looks similar to the SP4 but is made of ceramic and designed for high temperature and high resistance measurements. The HT4 accurately collects data at temperatures up to 650°C. The coaxial high temperature wiring also allows resistance measurements up to 10 Gigohms. The HT4 features spacing of .050 and .0625 inches and pressure is fixed at 180 grams. Tips are made of Tungsten Carbide or Osmium and a choice of .0016, .005, .010 inches radius.

QuadPro Test & Calibration

The system uses the Dual Configuration test method of ASTM Standard F84-99 to compensate for errors in probe spacing and errors caused by proximity to the edge of the conducting layer. NIST traceable calibration standards are available for purchase with the system. Proper use of the standards and the calibration procedure insures the specified system accuracy of better than 1%.

Specifications

|

Measurements |

Manual |

Auto |

High |

|

Range Rs (ohms) |

10-3 to 106 |

10-3 to 106 |

10-1 to 1010 |

|

Accuracy |

<1% |

<1% |

5X @ > 108 |

|

Test Time / Point |

10 sec |

2 sec |

Varies |

|

Dual Configuration Method |

Yes |

Yes |

No |

|

Display Resistivity or Thickness |

Yes |

Yes |

Yes |

|

|

|||

|

Sample Size |

300mm |

50-300 mm |

50-300 mm |

|

Shape Round or Square |

Yes |

Yes |

Yes |

|

Number of Points Measured |

5 - 25 |

5 - 49 |

5 - 49 |

|

Open Frame or Enclosure |

Open Frame |

Enclosure |

Enclosure |

|

TCR Option |

150 mm |

200 mm |

300 mm |

|

Temperature Range 5°C to |

500°C |

400°C |

300°C |

Automation: Select min temperautre, max temperature, interval and dwell time, then auto

Run Display: Temp, Rs, resistivity or thickness

Calculate TCR or Map Rs @ Temperature.

Output: 2D and 3D contour maps, save and get results, print results including contour maps, copy to clip board, etc. Retest function.

Probe Heads

|

Type |

Material |

PinSpacing |

Spring Pressure |

Tip |

Diameter |

|

SP4 |

Delrin |

40,50,62.5 mils |

45,85,180 grams |

TC or OSM |

1.6, 5 or 10 mils |

|

HT4 |

Ceramic |

50, 62.5 |

180 grms |

Same |

Same |

相关产品

光学斩波器和斩波片斩波器特性晶体稳定的锁相回路抑制低频漂移和相位抖动谐波,次谐波和分数谐波的和频和差频输出微处理器控制提供单频和双频叶片为泵浦探测和其它非线性实验提供谐频叶片用户设置存储在非易失性RAM,并可从中调用USB接口包含控制软件包MC2000B光学斩波器是一种精密仪器,利用先进的功能调制连续光束发出的光。其控制平台使用了锁相回路(PLL)电动速度控制设计,能精确保持斩波速率和参考信号的相

特性运动永磁电机设计,具有更快的响应(±0.2度是400微秒)高精密度(15微弧度)光学反射镜位置探测电流阻尼和错误限制器的模拟控制电路可选择反射镜镀膜(见下表)也提供客户定制的镀膜 该高速扫描振镜定位系统设计用于集成到OEM或定制的直径小于10毫米的激光束操控应用中。每个系统包括一个双轴振镜电机和反射镜组、相关的驱动卡和驱动卡散热器。另外还提供一个基板,使之能安装到Ø1/2英寸接杆和倾斜平台。低

特性厚度:60mm(2.4英寸)可供选择的尺寸范围从12英寸x12英寸(300 mmx300 mm)到36英寸x48英寸(900 mmx1200 mm)每个面包板都经过单独优化,测试,发货时附带一份测试数据报告证书边缘小孔距平台边缘1/2英寸(12.5mm),使可用区域最大化顶板:任意1平方米区域内的表面平整度为±0.1mm5mm厚的不锈钢顶板和底板,以及全钢侧板全部采用钢-钢连接可以提高热稳定性

ONLINE MESSAGE

在线留言

*注:请务必信息填写准确,并保持通讯畅通,我们会尽快与你取得联系